We are happy to share some project highlights from our collaboration with the Deloitte marketing team on their Best Managed Companies Gala Awards. We worked on several experiences including the en...

Our Company Culture

March 18, 2019

Hello friends, supporters, and digital design enthusiasts! We've been busy growing our space and team over the last 6 months. It's been a fantastic and reflective time from which we've learned an im...

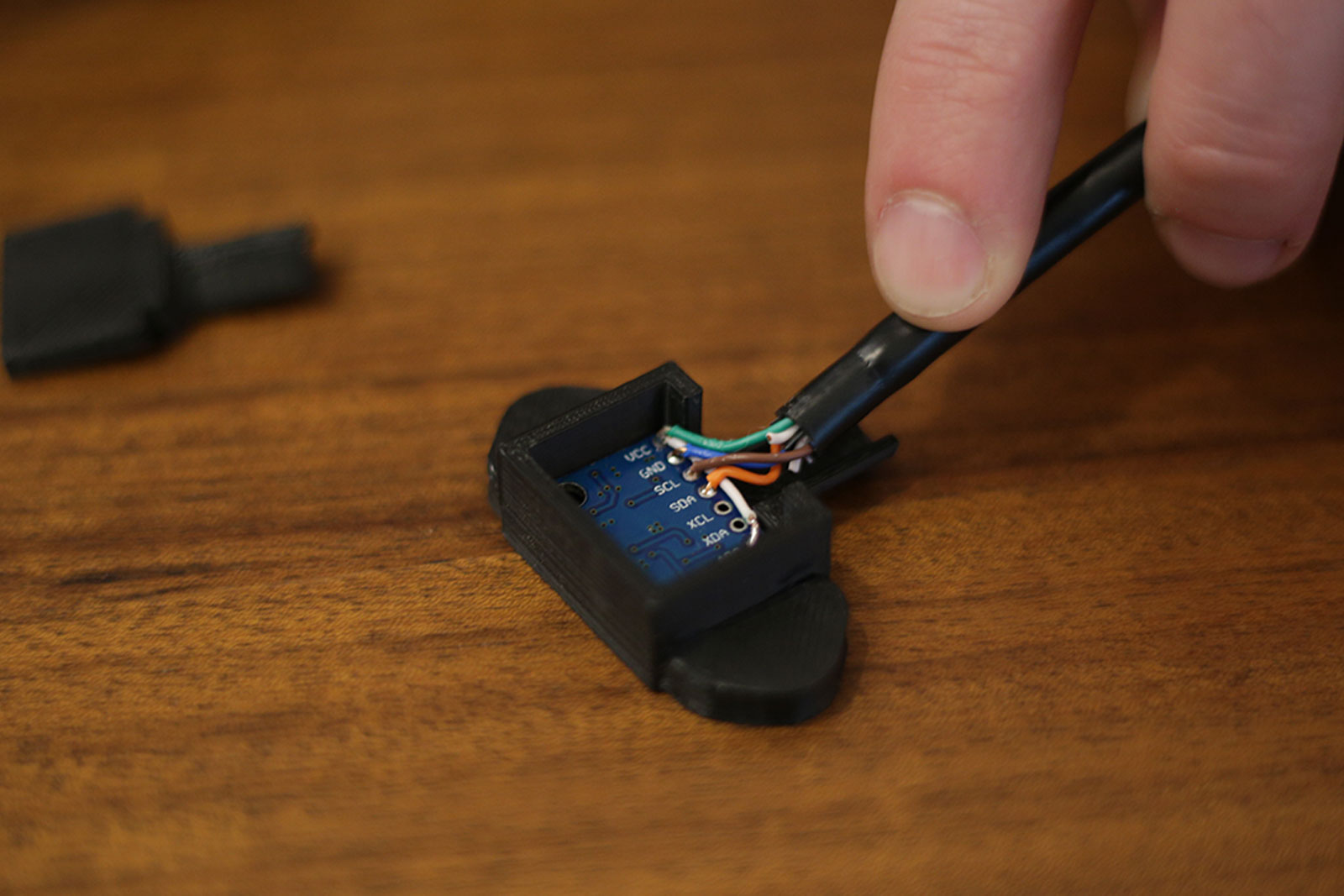

3D Printed Enclosures: Measure Company Culture in Real Time

April 17, 2018

Necessity may be the mother of invention, but sometimes it is opportunity that creates a context ripe for thoughtful design intervention. We talked to UX Designer Jared Foote of Deloitte Digital a...

Infinity Scope: Reflect on All That is Possible

March 14, 2018

Last year was huge for Hot Pop Factory thanks to our clients and collaborators who provide endless inspiration. When 2018 got underway we decided to repay the favour and express our appreciation wit...

Looking Back at 2017 and Looking Ahead

January 24, 2018

The new year is definitely in full swing and we couldn’t be more excited about what we have in store. Our team spent the break resting, reflecting, and catching up with families in the Netherlands...

Our Clients Looked Laser Sharp at the OOAK Tradeshow

December 5, 2017

Toronto’s annual One of a Kind Show is one of North America’s largest and most popular craft shows. Launched in 1975, it’s a boon for Southern Ontario maker entrepreneurs. We were proud (in ki...

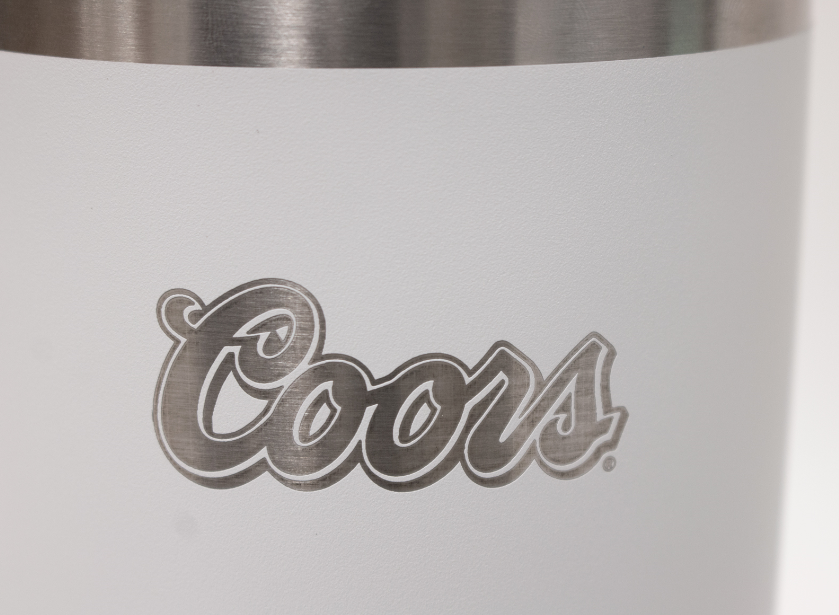

Custom Engraving Gift Guide

December 1, 2017

It's that time of year and searching for the perfect gift really can be easy. We've helped countless customers hit it out of the park with their loved ones and colleagues - by putting a personal t...

Amongst the throng of Toronto‘s densely populated coffee market, Pilot Coffee Roasters stand apart from the crowd. Ethical and diligent in sourcing beans from leading plantations in Brazil, Costa ...

How to Rock at Holiday Markets OOAK 2017 Edition

October 13, 2017Hello fellow makers! With holiday market season coming up, we put together some inspiration, and useful tips to help you prepare for a knockout booth display and efficient production to maxi...

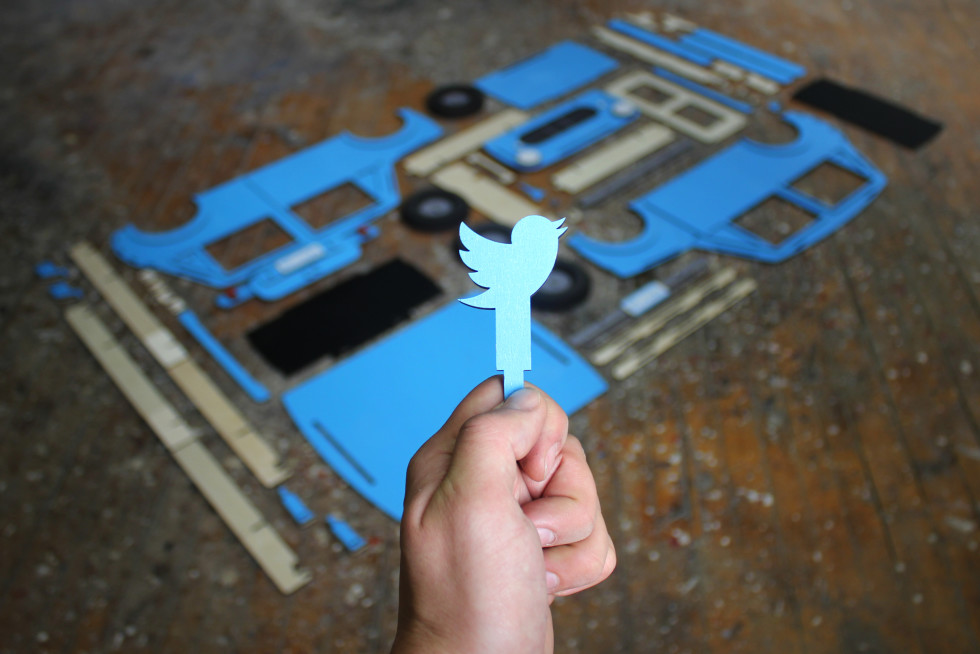

Case Study: Helping Twitter Stay On-Brand at Events & Trade Shows

October 10, 2017

Companies with singular products demand unique design solutions. For the last two years we’ve executed several projects for Twitter Canada and we’re really proud of the results. Since we’ve no...