Toronto’s Premier Laser Cut Wood Service

Laser cutting wood is a simple but effective manufacturing technique used to create many remarkable things. From small, products like business cards, and coasters to large eco-friendly signage, decorative artwork, stencils, and furniture the possibilities are endless.

Working with Hot Pop Factory designers can easily turn digital artwork into precisely laser cut wood pieces that have sharp details, smooth curves, and intricate patterns. Whether you are working on a small custom design or a corporate branding project, our 10+ years of design and production manufacturing experience can guide and execute your vision from idea to physical reality. We not only offer material sourcing and laser cutting services, we can also provide full design services. Lead Times include standard 5 business days, 48hr rush, and 24hr rush.

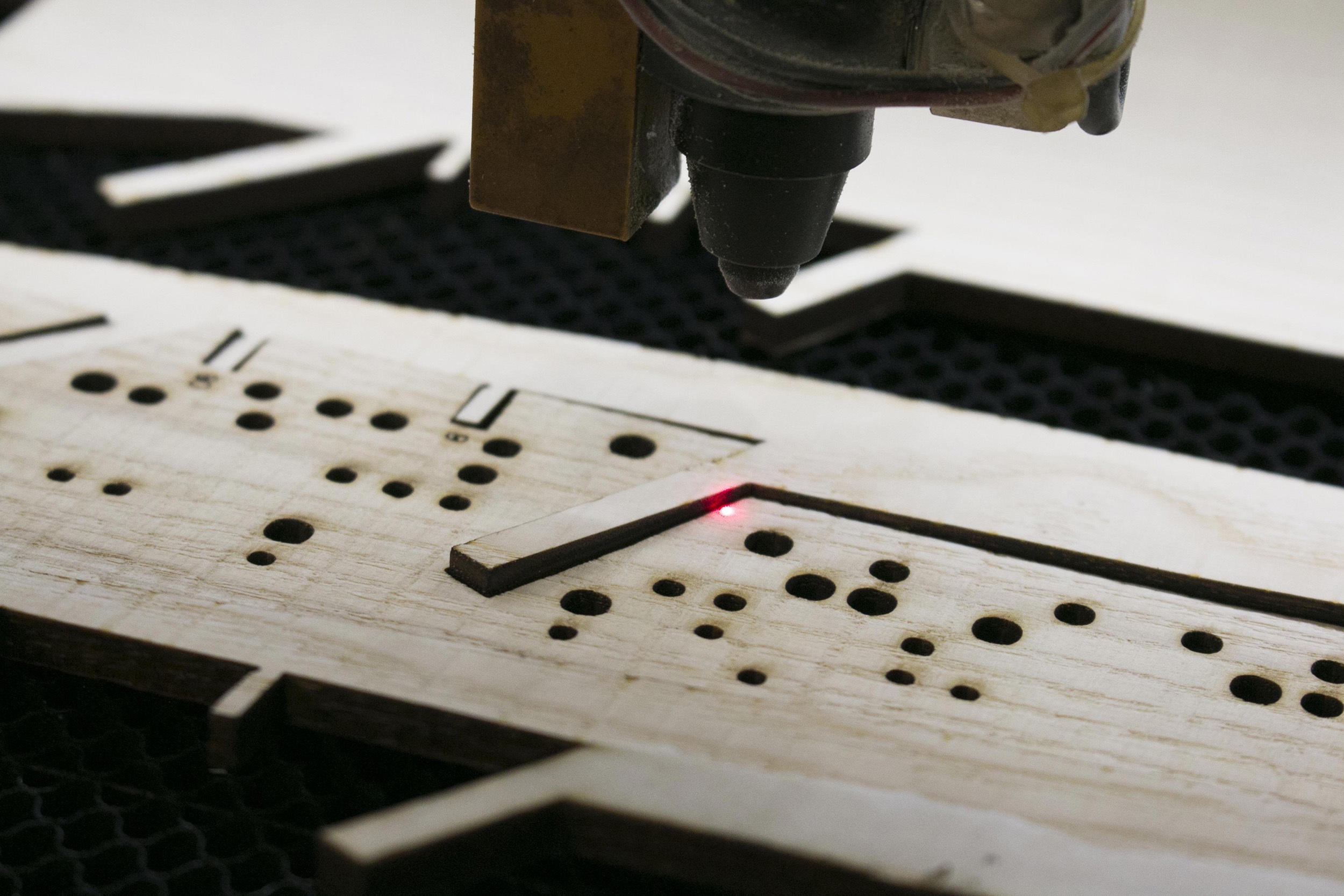

Wood Laser Cutting Explained

When a laser cutter processes wood, it works by shooting a laser beam at the material, evaporating the wood directly in its path penetrating the entire thickness. The result a clean, smooth, and perfect cut that saws and other traditional woodworking equipment can't accomplish.

Types of Wood We Laser Cut

Plywood

Plywood is a material manufactured from thin layers of wood veneer that are glued together with adjacent layers alternating. It is an engineered wood from the family of manufactured boards which includes medium-density fibreboard and particle board. Plywood offers many benefits such as water resistance, durability, and flexibility making it one of the most popular materials we laser cut.

Plywood cuts quickly with an attractive finish. The edge takes on a golden-brown look, engraving and scoring operations have a similar effect on the surface of the material. We stock Baltic Birch plywood in 1/8" and 1/4" thicknesses. We strongly recommend this species as other plywood types contain adhesives which don't cut as well in terms of speed and cut quality.

Hardwood

Depending on your product laser cutting a premium hardwood might be the best option for you. Woods like Maple, Cherry, Walnut and Oak to name a few are also easy to laser cut and allow for the creation of complex products with a high-quality finish like a beautiful wooden toolbox, cigar humidifier, custom furniture and much more.

Hot Pop has also teamed up with Leaf so designers can use urban wood from Toronto. Thousands of Toronto trees die of natural causes each year, and the city saves this material so designers and artists can reuse it in new ways.

Medium-Density Fibreboard (MDF)

Generally, denser than plywood medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. Like Plywood one can make just about anything when laser cutting medium-density fibreboard (MDF). However, since it’s denser, it can take longer and therefore, be more expensive to cut, sometimes leaving a much darker edge finish. We typically recommend customers to use plywood instead.

Learn more about the wood we laser cut here.

Benefits of Laser Cutting

Complexity of designs - Laser cutting allows for the creation of incredibly complex designs to be cut in a wide range of materials that is not possible with other cutting processes.

Unmatched precision - Laser cutting is a highly accurate and precise way of cutting wood. It allows for highly accurate cuts that leave a clean cut and a smooth finish unmatched by other cutting processes.

Non-contact process - Laser cutting only affects the area that is being heated and removes the risk of abrasions or damage to the surrounding area of the material.

Safety - Laser cutting is the safest cutting method as the laser beam used is tightly sealed in a lightbox.

Environmentally friendly - Laser cutting is an environmentally friendly cutting process that vastly reduces the amount of material wastage when compared to mechanical cutting processes and traditional woodworking tools.

Get started by sending us your vector artwork (.ai, . eps, .dxf, .svg), as well as your desired material and thickness to receive a quote from us in under 24hrs.

You're in good company.

Hundreds of companies across Toronto have entrusted Hot Pop Factory with all their laser engraving needs.