Three Mind Blowing Innovations in 3D Printing and Design

June 21, 2016

The most exciting part about 3D printing is that we’ve only scratched the surface of what is possible. So many designers and researchers are continuously innovating new techniques and materials that can be used for production. Here we take a sneak peek into the future of 3D printing with three breakthrough stories.

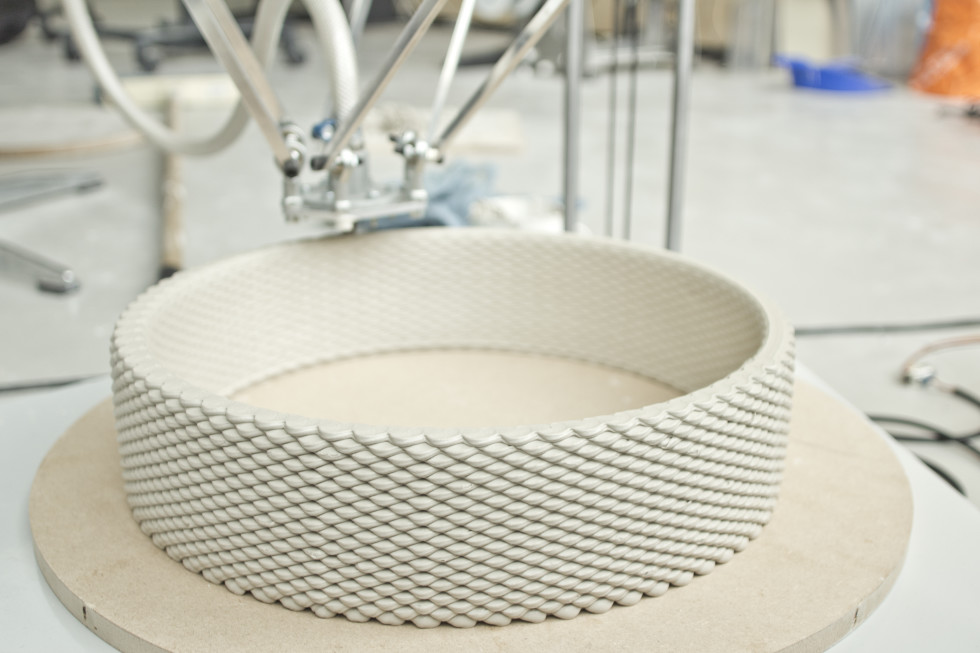

1) Woven Ceramics

When Olivier van Herpt, an industrial design graduate from the Design Academy of Eindhoven, started experimenting with 3d printing ceramics there weren’t a lot of options available. The printing beds on most desktop 3D printers were too small and food-safe printing was too costly. So the designer went to work and spent two years experimenting and developing his own 3D printer, extruder and process to make ceramics out of hard clay instead of the usual mix of clay and water (which tended to collapse). With these new tools, he was able to design a collection of ceramics that are beautifully woven into various patterns. Rather than trying to completely erase the layers of 3D printing, Olivier highlights them with detailed designs. On top of innovating with functional ceramics, the designer has also done experiments with 3D printed beeswax, prints that respond to sound and environmental sensors, a dripping printer and a drawing machine.

2) Replicating Hair

The hair on our bodies serves so many purposes: it acts like a sensor to the outer world, it helps us feel and touch, it helps to keep us warm. Cillia is a project out of the Tangible Media Group at the MIT Media Lab that replicated the various functions of hair with 3D printing. With their new method, the team was able to design hair geometry down to micrometres (that’s smaller than a millimetre!), and as a result, the researchers were able to make surfaces that could sense and adhere to other surfaces. The coolest part is that compared to the mostly hard surfaces that have been 3D printed so far, this project shows the possibility for giving 3D printing a softer touch.

3) Forming Metal Out of Thin Air

We were super excited when the 3Doodler came out a few years ago, giving us a way to do free-form prints that stand on their own in an instant. Recently, the Wyss Institute at Harvard University has come up with a similar technique but now with metal and lasers. These metal structures appear to float in the air without any support material and will allow for more flexibility when designing wearable sensors, circuits and other conductive materials.

What kind of ideas are you dreaming up? Check out the standard 3D printed materials we offer and how it can apply to your next project.

Images via: Olivier van Herpt, The Tangible Media Group and The Wyss Institute